Save Energy and Costs with Messung’s Energy Management Solutions

Energy management forms the basis for uncovering savings potential in your factory or organisation. An energy management system (EMS) monitors, controls, and optimises energy performance in a plant by measuring the generation, transmission, and consumption of energy. It also helps diagnose problems like poor power quality, over-consumption and leaks across the entire plant.

For industrial and large energy consumers, Messung is a smart energy management system supplier, offering IoT based Smart Energy Monitoring solutions to measure and analyse power usage, detect areas of wastage or mismanagement, and implement correctives to improve and optimise the situation.

Messung has joined hands with Janitza Electronics GmbH, Germany, to bring their advanced energy management products & solutions to benefit Indian industry.

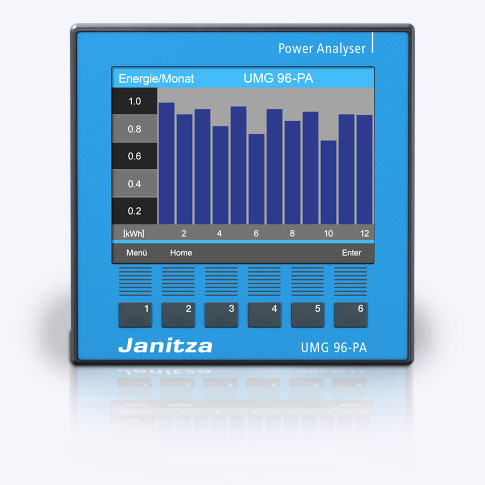

Janitza is a leading supplier of energy efficiency systems, renowned for R&D development, manufacturing & distribution of Power Quality, RCM & Energy Monitoring Solutions. As their Mega Distributor for India, Messung presents Janitza’s world-renowned technology and products – for continuous and reliable energy data management (e.g. ISO 50001), power quality monitoring and residual current monitoring.

Highlights of Janitza’s product range

Messung’s integrated EMS

Messung designs and installs industrial energy management systems keeping three key factors in mind.

Correct installation: By using Class A power quality analyser UMG 512 PRO at the PCC level and a number of UMG 509 QA, and UMG 96 PA at appropriate power consumption areas, and the GridVis EMS software; Messung provides complete visibility of the electrical usage in your organisation.

Accuracy: Accuracy means the device(s) must measure and collect the right data.

KPI Monitoring: Choosing the right KPI and monitoring it accurately from a KPI platform can be crucial to the plant efficiency. In consultation with customers, Messung discusses and decides strategies to meticulously control Tariff charges, including KVAH/KVAR billing, MD, TOD, and many other critical parameters.

All the field information is integrated into a system or KPI platform to analyse all the data, so it becomes easy to make better decisions and improve your plant’s energy consumption.